Existujúce čerpadlo - Viacstupňové

Náhradné čerpadlo Zoznam náhrad

Poznámka

Informácie o produkte

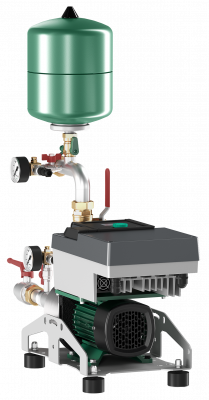

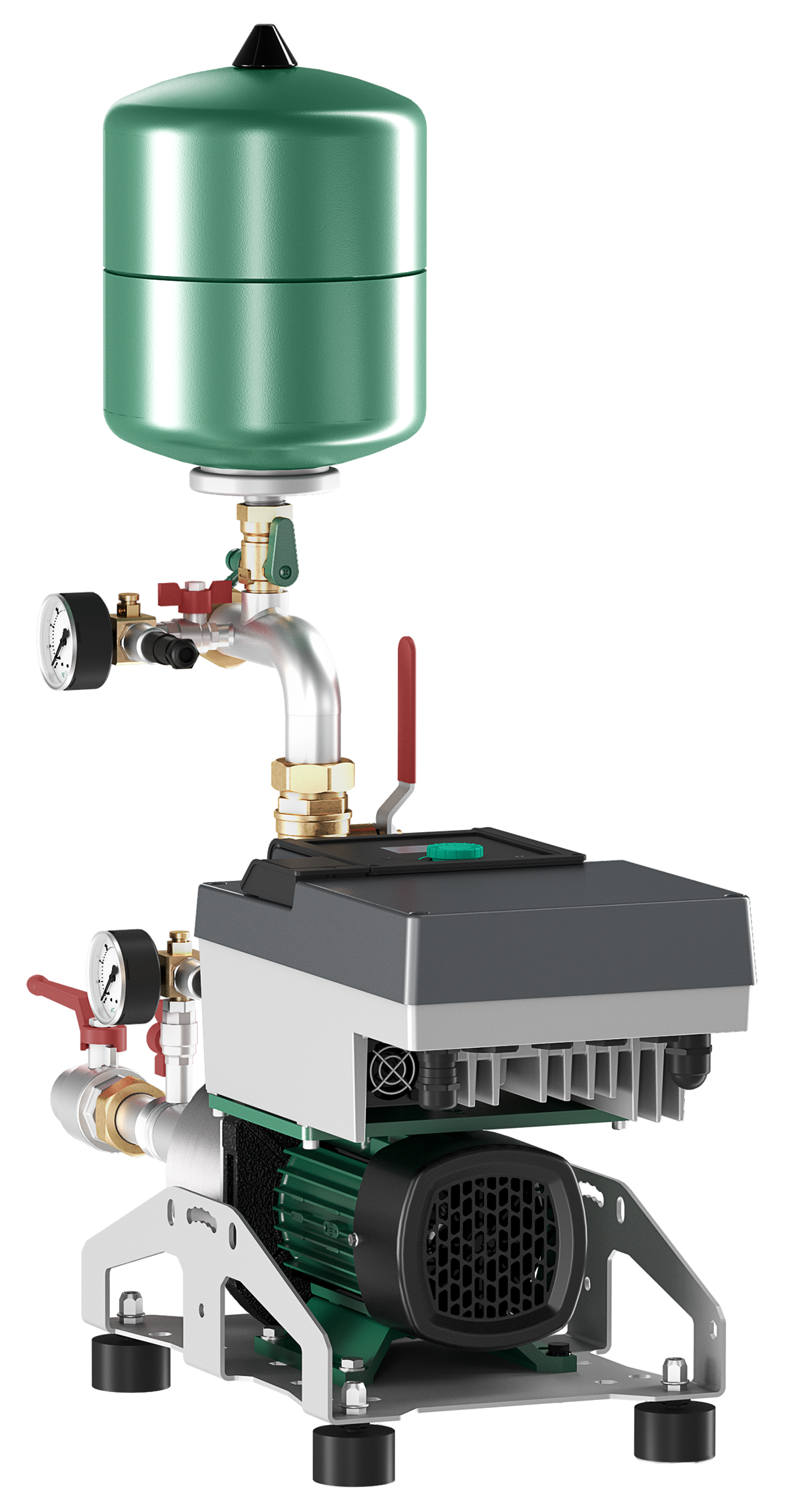

Isar MODH1-E-1-CH3-LE-205

Pressure-boosting system with one non-self-priming stainless steel high-pressure multistage centrifugal pump.

Application

Fully automatic water supply and pressure boosting in inlet mode, either from the public water supply network or from a tank, for domestic, commercial, industrial and municipal applications (e.g. residential, office, administration buildings, hotels, hospitals, trades, industry, water supply companies).

Pumps drinking water, process water, cooling water or other industrial water, which does not affect the materials used, neither chemically nor mechanically, and does not have any abrasive or long-fibre constituents.

Equipment/function

- 1 Medana CH3-LE pump per system

- Components that come in contact with the fluid are corrosion-resistant

- Electrogalvanised base frame with height-adjustable oscillation absorbers for insulation against structure-borne noise

- Stop valve on every pump on the suction and discharge sides

- Non-return valve, on the discharge side

- Pressure sensor, on the end pressure side

- Pressure gauge optional, on the suction side

- Pressure gauge, on the end pressure side

- Low-water cut-out switchgear

- Control via integrated frequency converter

Mains connections:

- 3~400 V ± 10%, 50 Hz;

-

3~380/440 V ±10%, 60 Hz;

depending on type also 1~230 V, 50/60 Hz (other versions on request) - Max. fluid temperature: 50 °C (70 °C optional)

- Max. ambient temperature: 40 °C

- Operating pressure: 10 bar

- Inlet pressure: 6 bar

- Nominal connection diameter for end discharge side: R 2"/DN 100

- Nominal connection diameter inlet side: R 2"/DN 100

- IP rating: IP54

- Fuse on mains side: A, AC 3 according to motor power and EVU regulations

- Cooling water

- Drinking and process water

Single pump:

- Impellers, stage chambers and pump housing made of stainless steel 1.4301/1.4404

- Shaft of stainless steel 1.4404

- EPDM gasket (EP851)/FKM (Viton)

- Mechanical seal made of tungsten carbide/carbon

- Bearing of tungsten carbide

- Pump support foot made of aluminium

- Base frame: electrogalvanised and with height-adjustable oscillation absorbers for comprehensive insulation against structure-borne noise; other versions on request

- Pipework: complete pipework made of stainless steel, suitable for the connection of all piping materials used in building services; the pipework dimensions must correspond to the overall hydraulic performance of the pressure-boosting system.

- Pump: One pump from the Medana CH3-LE series 2.., 4.., 6.., 10.., 16..; all pump components that come in contact with the fluid are made of 1.4301/1.4404 stainless steel.

- Valves: each pump is equipped on the suction and discharge side with a stop valve or with annular shut-off valves and a discharge-side non-return valve.

- Diaphragm pressure vessel: 8 l/PN 10 on the end pressure side with butyl rubber diaphragm, completely safe according to the food safety regulations; ball valve and drain and throughflow fitting according to DIN 4807 for test and inspection purposes

- Pressure sensors: 4 to 20 mA, one each on the suction and end pressure sides for pressure control by the integrated frequency converter.

- Pressure indication: Pressure gauge (ø 63 mm) on the end pressure side; additional digital display of the end pressure in the graphics display of the pump

- Controller: the control of the system is realised by the frequency converters integrated in the pump

Scope of delivery

- Factory-mounted, pressure-boosting system ready for connection and checked for functionality and impermeability

- Installation and operating instructions

- Factory test protocol